Fire & Smoke Curtains (Active Fire & Smoke Barriers) are an integral part of many building’s life safety systems and as such require a service and maintenance protocol suited to the building type and occupancy.

There are several national and international standards that should be adhered to as well as the recommended manufacturers guidance. BS8524-2: 2013 sets out the latest requirements to active fire barriers, EN12101-1: 2005 +A1:2006 provides information relating to the operation of active and static smoke barriers and all come under the guidance of BS9999: 2017 and where relevant, the appropriate areas of Approved Document B.

F&S Maintenance Ltd can provide scheduled and pre planned maintenance to comply with the above including a full, asset driven photographic report with any advisory works or remedials noted regardless of the manufacturer or age of the equipment.

If the asset requires a repair, F&S Maintenance can advise whether this is cost effective compared to a new assembly, repair in place if possible, recommission and retest. Always with a full photographic report to follow.

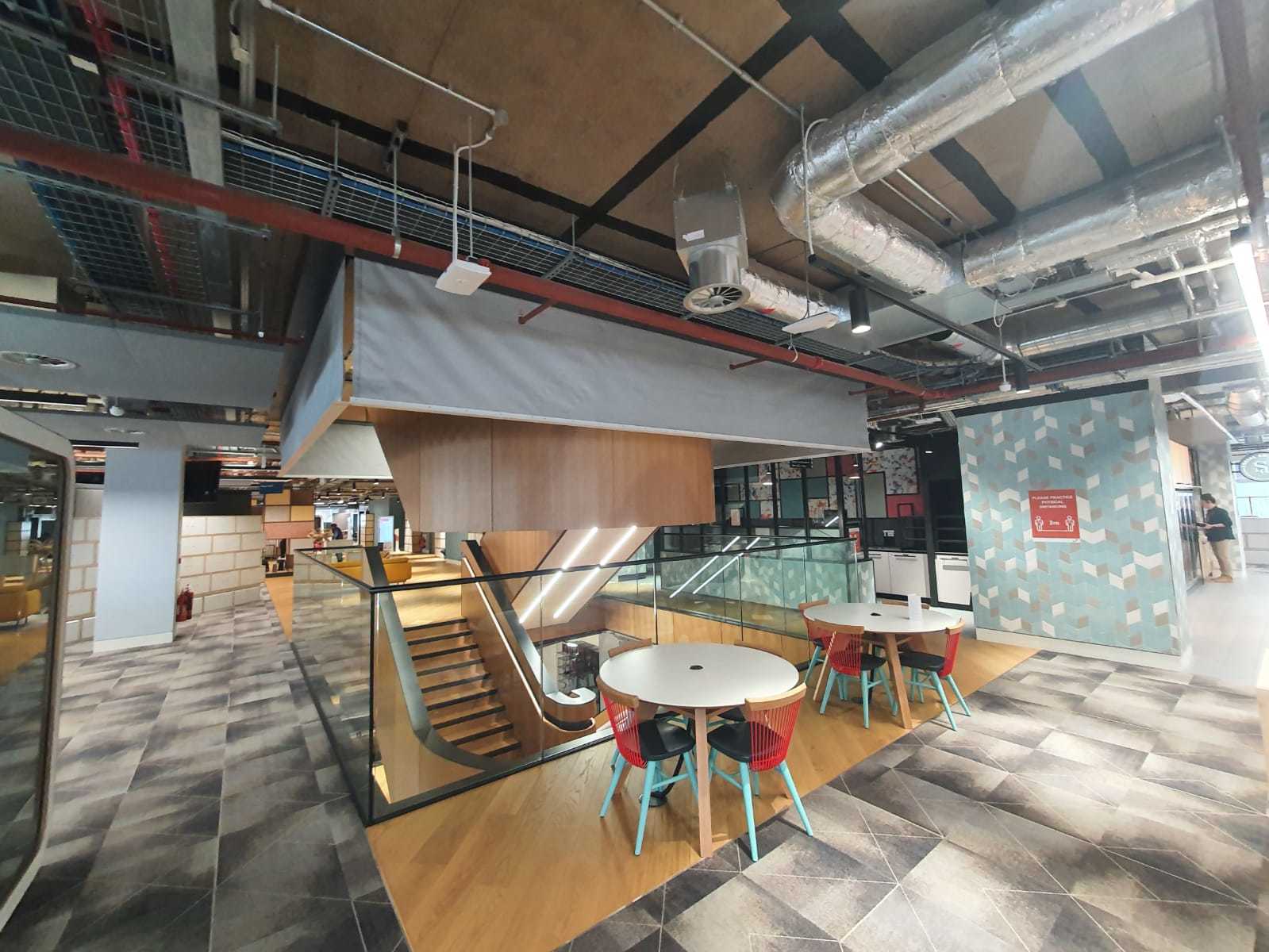

Often buildings have a complex network of multiple curtains triggered via a sequence of alarm signals, department stores and large office blocks for example. F&S Maintenance Ltd have a great deal of experience in testing these systems utilising the often-interconnected series of curtain group control panels.

Automatic Fire Curtains

Automatic fire curtains are manufactured using fire resistant fabric which is fixed to a steel roller and weighted using a bar on the bottom edge.

The roller is enclosed in discreet steel casing and is driven by an internal tubular electric motor.

The sides of the curtains are held securely in side channels and when it is activated by a fire detection system it closes flush to the floor.

An automatic smoke curtain operates in a very similar way to an automatic fire curtain but it normally closes above head height to create a smoke-free layer.

Multiple Roller Fire Curtains

Fire curtains with multiple rollers use the same gravity fail safe method of operation as single roller fire curtains.

Rollers with a diameter of 76 mm will be used for all multiple roller fire curtains The head box is manufactured from 1.2mm galvanised steel. The box can be powder coated to any standard RAL finish. As shown in the diagram below the rollers will include for a 600mm overlap.

The rollers must be positioned one above the other (over & under) to prevent the curtain gaping at the top and losing integrity. Curtains with a drop of 3.0m or less would be housed in a head box with dimensions of 180mm wide x 290mm high.

FC240 & FC60 Fire Curtains

FC240 and FC60 curtains incorporate the latest technology to allow gravity fail safe operation and also to eradicate the need for limit switches.

The integral tubular motor and the motor control circuit together provide a current limiting facility for the upper curtain position and back EMF generation for the controlled fail safe descent.

Fire and test deployment is always by gravity, even when the mains and battery supplies are available.

This system will operate under worst case (mains and battery failure) conditions. All fire curtains use rollers of 76mm diameter.

The headbox is manufactured from mild steel angle with an overall dimension of 42mm having a weight of 1.76Kg per linear metre.

For curtains less than 2.3m wide a 4.3Kg per linear metre bottom bar would be used to ensure correct deployment under gravity.

The ‘T’ bar can be powder coated to any standard RAL finish.

Automatic Fire Curtains

Automatic fire curtains are manufactured using fire resistant fabric which is fixed to a steel roller and weighted using a bar on the bottom edge.

The roller is enclosed in discreet steel casing and is driven by an internal tubular electric motor.

The sides of the curtains are held securely in side channels and when it is activated by a fire detection system it closes flush to the floor.

An automatic smoke curtain operates in a very similar way to an automatic fire curtain but it normally closes above head height to create a smoke-free layer.

Multiple Roller Fire Curtains

Fire curtains with multiple rollers use the same gravity fail safe method of operation as single roller fire curtains.

Rollers with a diameter of 76 mm will be used for all multiple roller fire curtains The head box is manufactured from 1.2mm galvanised steel. The box can be powder coated to any standard RAL finish. As shown in the diagram below the rollers will include for a 600mm overlap.

The rollers must be positioned one above the other (over & under) to prevent the curtain gaping at the top and losing integrity. Curtains with a drop of 3.0m or less would be housed in a head box with dimensions of 180mm wide x 290mm high.

FC240 & FC60 Fire Curtains

FC240 and FC60 curtains incorporate the latest technology to allow gravity fail safe operation and also to eradicate the need for limit switches.

The integral tubular motor and the motor control circuit together provide a current limiting facility for the upper curtain position and back EMF generation for the controlled fail safe descent.

Fire and test deployment is always by gravity, even when the mains and battery supplies are available.

This system will operate under worst case (mains and battery failure) conditions. All fire curtains use rollers of 76mm diameter.

The headbox is manufactured from mild steel angle with an overall dimension of 42mm having a weight of 1.76Kg per linear metre.

For curtains less than 2.3m wide a 4.3Kg per linear metre bottom bar would be used to ensure correct deployment under gravity.

The ‘T’ bar can be powder coated to any standard RAL finish.